Telephone:

+8613673691936

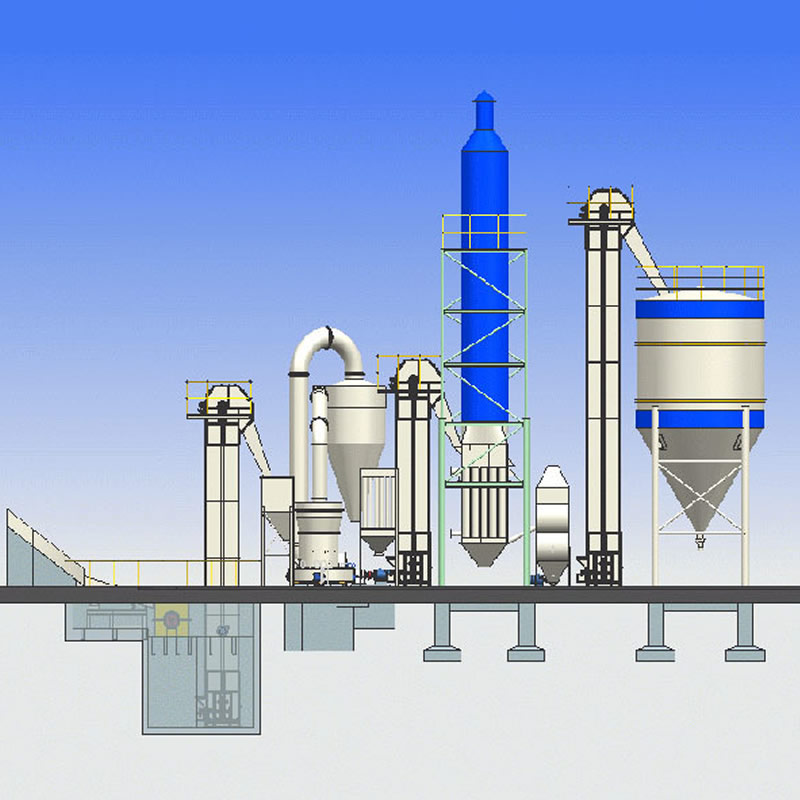

The Working Process

The process flow of the gypsum powder production line is:

raw ore crushing – grinding – calcination – cooling – finished product packaging

1. The crusher crushes large-sized gypsum ore into small particles smaller than 25mm and sends them into the raw material silo;

2. The gypsum particles in the raw material silo are transported to the mill for grinding, and the fine gypsum raw powder is sent to the raw material silo through a powder selection machine;

3. Gypsum powder is sent to a fluidized bed furnace for calcination; The calcination heat source usually uses a thermal oil boiler or a air heater.

4. The calcined gypsum powder is cooled and sent to the clinker silo for storage and aging;

5.Measurement and packaging of finished gypsum powder.

Introduction to Fluidized Bed furnace Process

In the production process of gypsum powder, gypsum calcination is a key link. Based on years of exploration and research, we have developed a more excellent calcination equipment – fluidized bed furnace.

Working principle of fluidized bed furnace:

The main body of the fluidized bed furnace is composed of heat dissipation coils, which are filled with heat transfer oil. After heat exchange, the heat is released into the fluidized bed furnace. Roots blower, through the air distribution plate at the bottom of the fluidized bed furnace, blows cold air into the furnace, blowing the powder inside the furnace to reach a boiling state. Gypsum powder is calcined at a certain temperature to remove crystalline water, and after its weight becomes lighter, it automatically flows to the discharge port. The gypsum powder produced by the fluidized bed furnace calcination process has stable quality, and the crystal water content and initial and final setting time are easy to control.

Advantages of fluidized bed furnace:

1. The fluidized bed furnace has no rotating components, and its structure is simple and not easily damaged;

2. Compact equipment with minimal footprint;

3. Low heat and electricity consumption;

4.The finished product has good quality and the composition of gypsum is relatively ideal.

Previous:

Next:

©2023 HENAN KSTONE MACHINERY AND ELECTRICAL EQUIPMENT CO., LTD 备案号:豫ICP备2023021393号