Telephone:

+8613673691936

Aerated Autoclaved Concrete block production line (AAC production line)

Provide one-stop services such as process design, equipment manufacturing, installation and debugging guidance for the daily production line of 70-1000m3 aerated concrete blocks.

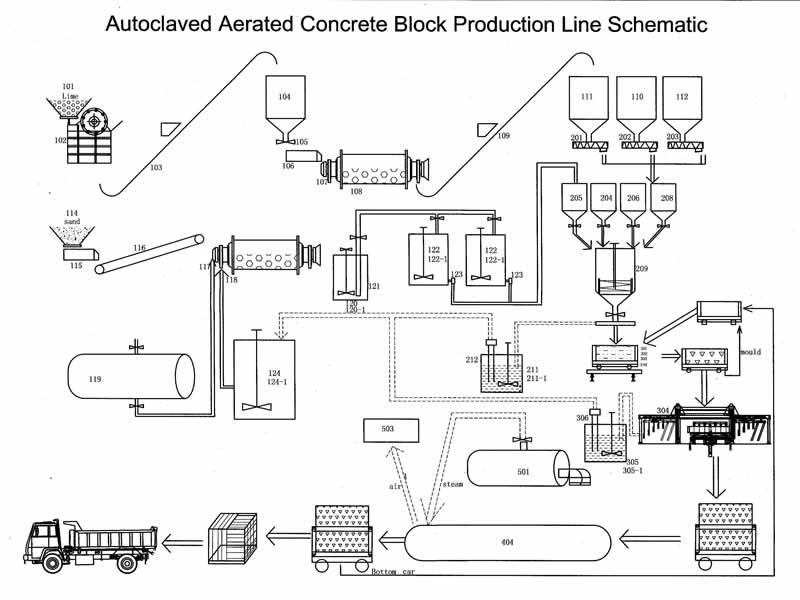

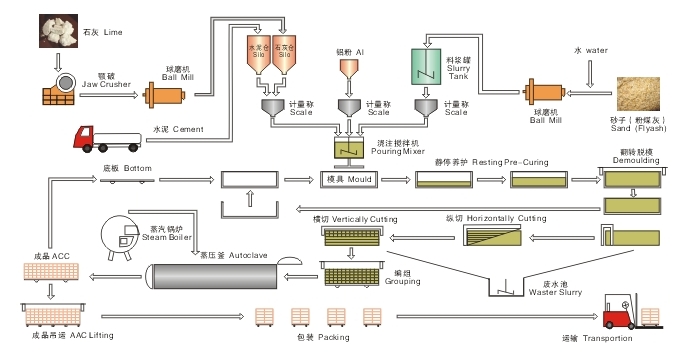

AAC process flowchart

Engineering Process:

1.preparation of Raw Material:grinding lime and sand respectively; putting lime, cement into the silo for reserve, sand (or fly ash) made slurry for later reserve(flyash can make slurry without grinding).

2.Ingredient:dose and match measured raw materials.

3.MIXING: feed raw material into pouring mixer to make slurry mixture.

4.POURING:after thoroughly mixing,the slurry is poured to mould

Resting and Pre-curing:After pre-curing under a certain temperture and time,the block would reach a certain hardness prepare for cutting

6.Demoulding: take off the mould by hoister,

7.Overturn-cutting: body turn by 90º, standing on the slip table and move to the destination for horizontally and vertically cutting as well as six-side cutting.

8.GROUPING: the body is set on the steam-curing cart by the unfinished products hoists, put on two mould each cart, then grouping the cut blocks and put them into autoclave,

9.STEAM CURING: steam curing and hardending the bodys under a certain temperture and press,

10.Take finished products out of autoclave,

11.The finished product hoister take the finished product to stock shield, then pack for loading

12.The bottom (side plate) and cart return back,

13.The bottom (side plate) would be organized with open mould, then cleaning and oiling for next pouring.

Previous:

Next:

©2023 HENAN KSTONE MACHINERY AND ELECTRICAL EQUIPMENT CO., LTD 备案号:豫ICP备2023021393号